Item # FLOW CONTROL EXPLAINED

BRIEF OVERVIEW OF FLOW CONTROL AND HOW IT WORKS

- UM : EA

Flow Control

What is it, how does it Work, and what are its applications?

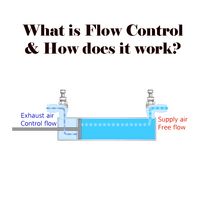

In a pneumatic system, actuator speed is managed using a pneumatic flow control device. The flow controller uses a built-in needle valve in conjunction with an integrated check valve to adjust the amount of air flowing through the system. There are two types of flow control that are utilized in a closed pneumatic system, Meter-Out and Meter-In.

Meter-Out control is the most used type of flow control and is best suited for double acting cylinders. The speed of the actuator is altered by adjusting the exhaust air flow leaving the system. While the air supply entering a Meter-Out controlled system remains constant, an internal check valve directs all exhausted air through the needle valve. This needle valve is adjusted to restrict the flow of air leaving the cylinder. More air exhausted results in faster speed, less air results in a slower speed. Meter-Out control is useful for:

- Higher Speed Pneumatic Systems

- Rodless Cylinders

- Cylinders with stroke over 3”

- Slides

Meter-In control is the most suitable for speed control of a Single acting cylinder. The cylinder speed is controlled by altering the supply of air at the intake with the needle valve of the flow control. The internal check valve in a Meter-In flow control directs all incoming air to the needle valve. The exhaust air is not controlled, and the cylinder returns by use of an internal spring. More air flowing through the intake results in faster speed, less air flowing through the intake results in a slower speed. One potential issue when using Meter-In flow controls is that the reduced air flow to the cylinder can be insufficient to smoothly overcome the internal friction of the seals, resulting in ‘chatter’ or an uneven rate of extension. Meter-In control is useful for:

- Slower Speed Pneumatic Systems

- Single Solenoid spring return cylinders

- Controlling air blowing out downstream – i.e. an air knife or chip clearing nozzle

NOT FINDING WHAT YOU NEED?

SEND US AN E-MAIL:

SALES@THEPNEUMATICSTORE.COM

Specifications

| ARTICLES REGUARDING | AUTOMATION COMPONENTS |