FLOW CONTROLS

Flow Control Information

Definitions and Diagrams

Flow Control Information

Flow controls are also known as speed controls or one way throttle valves.

Primary function: To limit the flow of air in one direction and have unmetered air in the return direction.

Primary Usage: To control the Speed of a pneumatic cylinder to extend or retract. This device will reduce the Cv and SCFM of a circuit to dial in the speed.

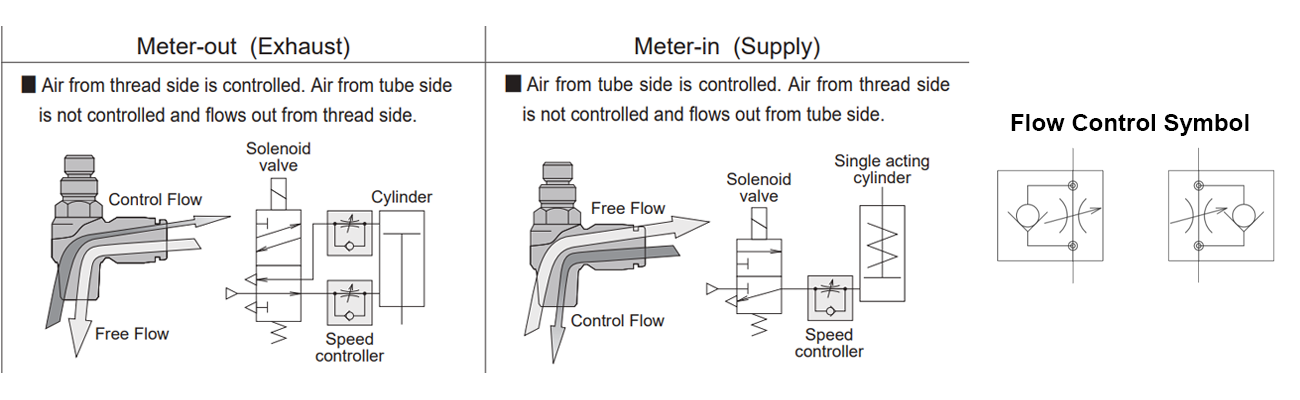

Recommendation: Flow control typically works best when controlling the exhaust of a cylinder (Meter Out), not the inlet flow. Exceptions would include single ported cylinders.

Common Misconceptions: Flow controls should not be used to control pressure and force, only speed and flow.

Definitions:

Cv (coefficient of flow): This is unitless coefficient applied to pneumatic calculations to indicate air flow to your device. The higher the number, the higher the flow. Flow Controls reduce this number.SCFM (standard cubic feet per minute): Volumetric flow rate at a given pressure.

Meter In: Controls the flow of the pressure going into the cylinder.

Meter Out: Controls the flow of the exhaust coming out of the cylinder.

Full Flow: This is in reference to the unmetered direction and has no restricted flow in the unmetered direction.

Symbol: This is the ANSI or ISO symbol that represents the device.

Tube Size: This is in reference to the tubing OD that will connect to the device.

Thread Size: This is the thread that typically screws into the cylinder, but if not tube connection is present it will also be the inlet thread size.

Inline: Flow controls can be flipped end for end to become Meter in or meter out.

No items found.